汽车连接器常见故障类型分析及注意事项

- 2024-11-22

- 2779

- 乐清地宏

- 返回上一页

一、背景介绍

随着汽车工业快速发展,人们对汽车功能的安全性和可靠性要求不断提高,汽车连接器作为连接车身线束纽带,其安全性和可靠性备受关注。基于连接器使用反馈,对其常见故障类型进行总结分类,为人们了解失效形式及分析失效模式提供参考。

二、故障类型分析

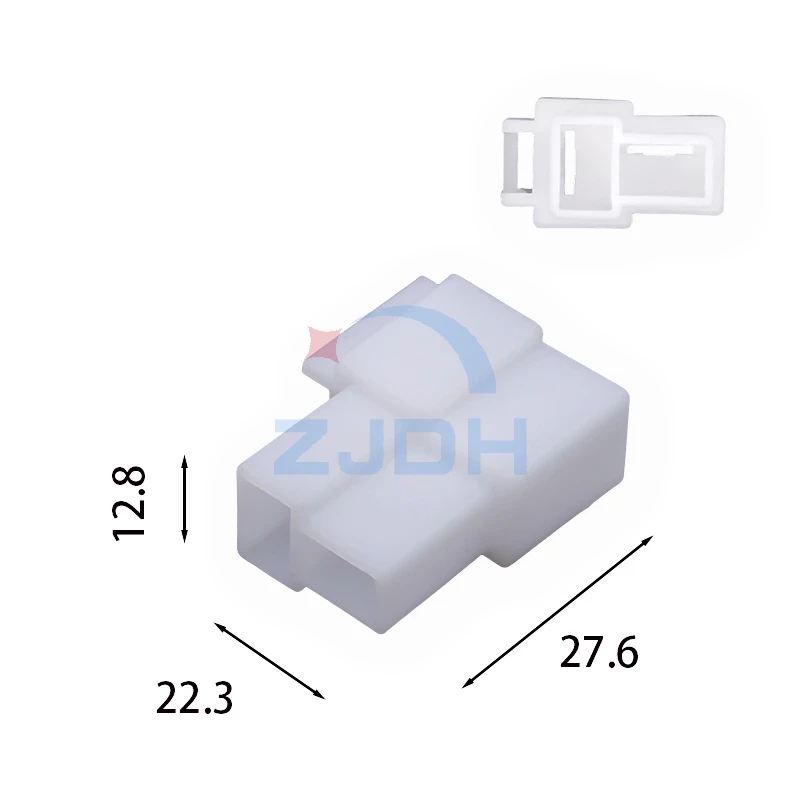

护套破损

护套功能及材料特性:护套多由高分子工程塑料制成,为端子提供支撑与绝缘保护,但其分子链对外界环境敏感,不同环境下材料强度、韧性变化易引发问题。

导致断裂的因素:包括护套材料水分含量超标、注射温度不合适、注塑机型号与产品不匹配、铰链相关因素(如铰链长度与厚度比值小)以及原材料本身韧性低等。

预防措施:严格控制护套材料的水分含量,在注塑生产前进行标准化干燥操作。优化注塑温度参数,确保温度在合适范围内,避免分子链断裂和重新结合。选择与产品匹配的注塑机型号,避免因设备不匹配导致材料性能下降。对于铰链产品,合理设计铰链长度与厚度的比值,降低断裂风险。在前期设计时,充分考虑产品使用环境,选择韧性合适的材料。

终端位移

故障影响:会使连接器电流或信号传输中断、功能丧失,属于严重故障模式。

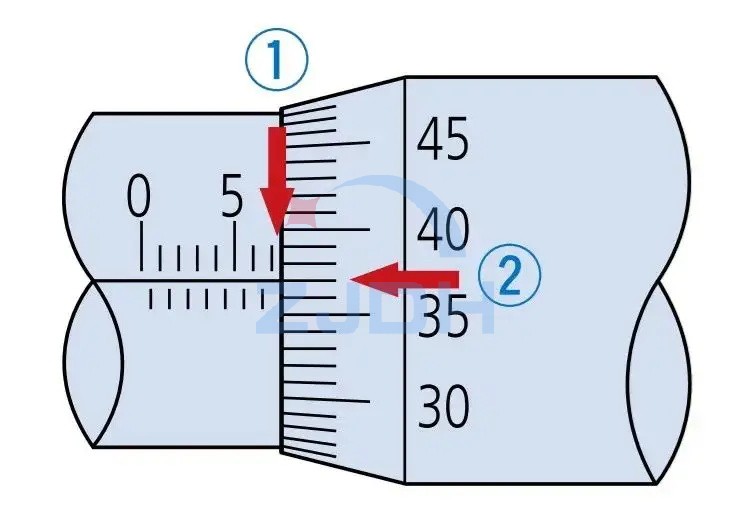

产生原因:一是组装过程中,因工人未按要求操作,端子没正确安装导致虚挂易脱落;二是产品结构方面,端子或护套连接结构强度不足,受张力影响可能拉出;三是连接器对齐中心偏移,存在如中心距尺寸不一致、间隙过大等多种情况导致端子移位。

预防措施:加强对组装工人的培训,严格要求其遵守 “一插二听三拉” 的操作规范,确保端子正确安装并与护套有效连接。在产品设计阶段,优化端子和护套的连接结构,提高其强度,确保端子在护套中的保持力符合标准要求。严格控制连接器的尺寸精度,确保中心距一致,减小连接器之间的间隙,同时优化插头端子与插头护套腔之间的配合结构,为端子提供可靠的定位。

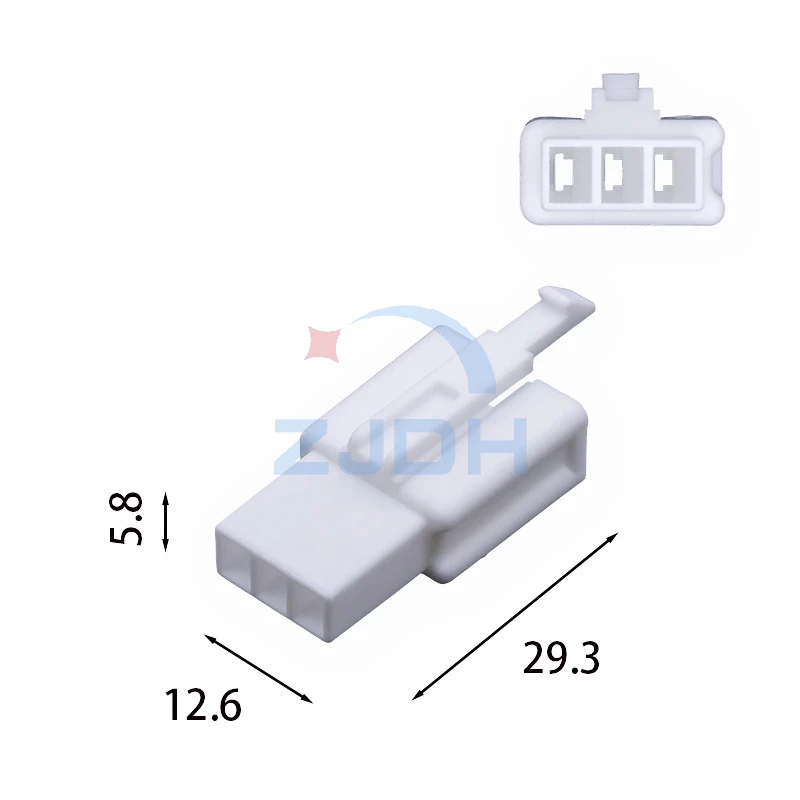

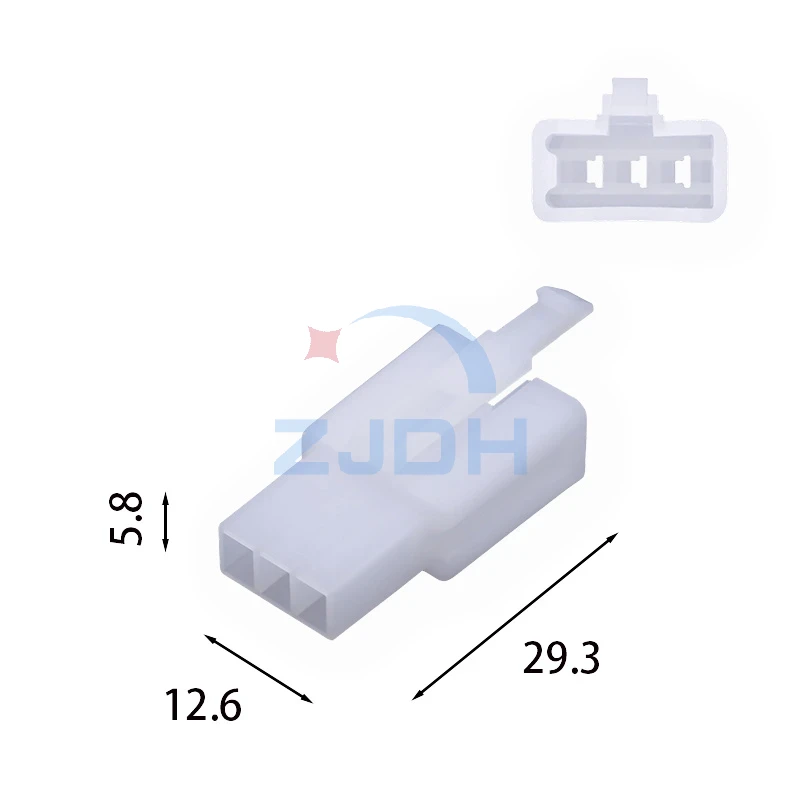

密封失效

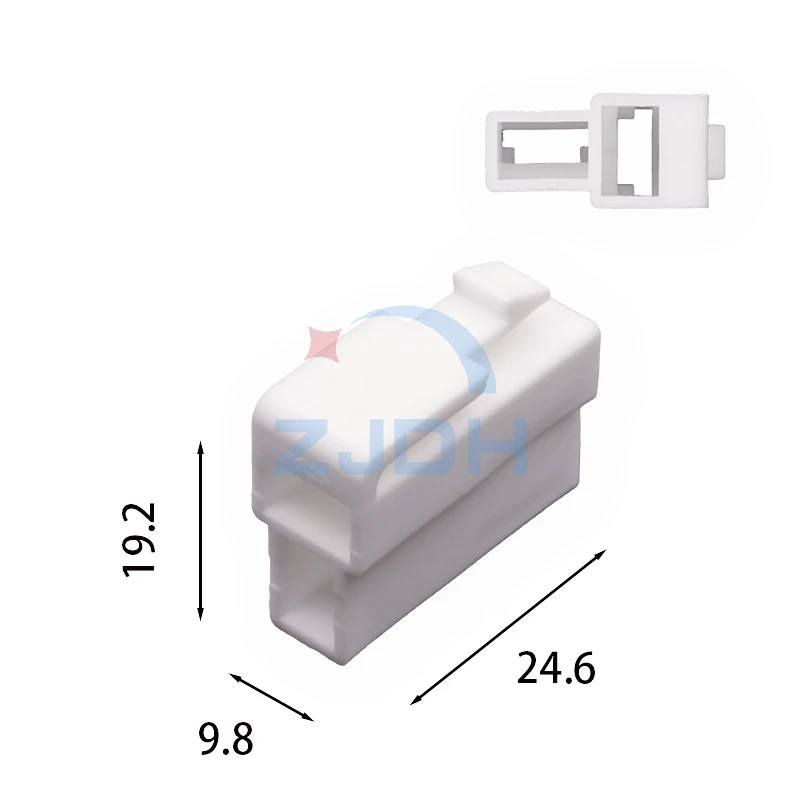

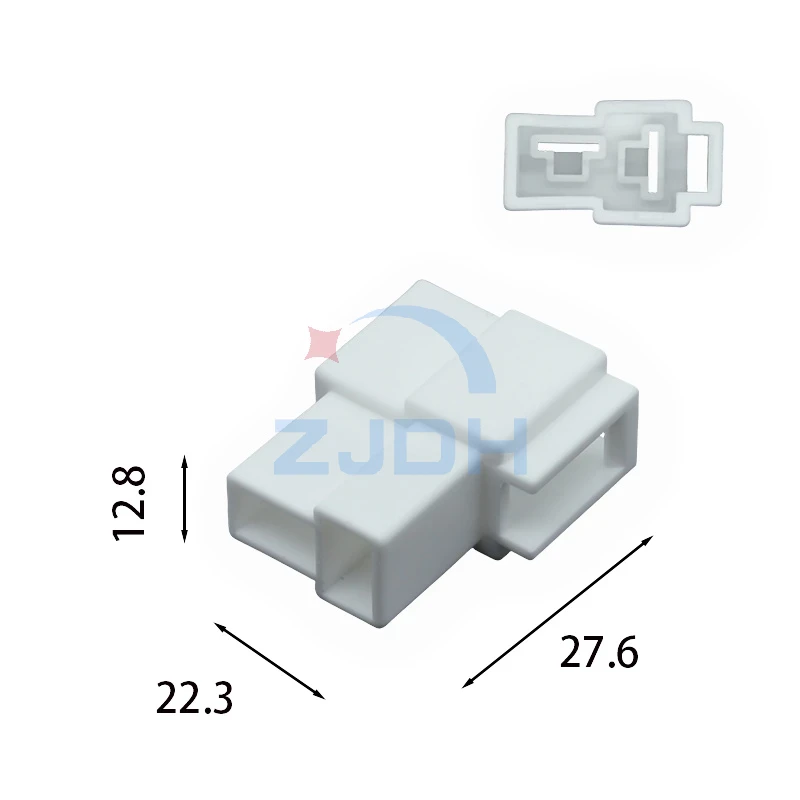

密封元件及形式:防水元件有密封圈和密封塞,密封圈分轴向、端面密封,密封塞分单个和整体式,各有其密封方式及作用区域。

失效表现及原因:密封肋有间隙缺陷、护套密封区域存在注射缺陷、密封干扰不足、高温老化后塑性变形等可致密封失效,整体式密封塞在端子组装时易因端子头外观问题导致内圈密封区撕裂。

预防措施:在生产过程中,严格控制密封圈和护套密封区域的光滑度和平整度,避免出现接缝、毛刺、注射不足等缺陷。选择能够满足高温老化要求的密封圈材料,提高密封的可靠性和耐久性。对于整体式密封塞,要求兼容的端子头必须光滑,无棱边、毛刺等外观缺陷,在端子组装过程中小心操作,避免密封塞内圈密封区撕裂。

端子弹簧故障

弹片作用及失效影响:端子弹片提供可靠正压保证端子间有效接触及电流、信号传输可靠性,弹片失效会导致触点失效。

失效原因及解决办法:包括弹片间隙尺寸过大、电检探头卡住使弹簧过度受压、返修操作不当、弹簧根部弯曲弧太小等。

预防措施:在生产过程中严格控制弹片之间的间隙和电弧根的大小,确保符合设计要求。定期检查电气检查治具,确保其正常运行,避免探头卡住弹簧。规范返修和维修站的操作流程,避免因操作不当导致端子弹片过度压缩而不反弹。

三、总结

连接器故障形式涵盖破损、端子错位、密封问题和端子弹簧故障。在连接器设计选型时,要依据使用环境确定性能测试项目,同时严格遵循操作规范,避免因操作不当产生缺陷。通过采取有效的预防措施,可以提高汽车连接器的可靠性和安全性,为汽车的正常运行提供保障。

- 上一篇:解锁汽车系统:连接器和端子

- 下一篇:连接器的基础扫盲(精读)

简体中文

简体中文

しろうと

しろうと

한국어

한국어

English

English

Русскийязык

Русскийязык

Français

Français

Deutsch

Deutsch

Español

Español

Português

Português

بالعربية

بالعربية

हिन्दी

हिन्दी

Việt Nam

Việt Nam

คนไทย

คนไทย

Türkçe

Türkçe

网站首页

网站首页 产品中心

产品中心 对比搜索

对比搜索 电话咨询

电话咨询